After several posts that featured things I did during my time off, I thought I would focus this post more on the nuts and bolts of what I am doing here, so here is some information about the seismometers and other instruments we have here in Antarctica. Out at the Castle Rock test site we currently have some T-240s and and a Nanometrics 120PA. Soon some 120 PHQs will show up for an upcoming experiment, and those will be huddle-tested at Castle Rock. The T-240s are in a sort of “snow vault” that is covered with plywood. Then the snow accumulates, so the whole vault is buried 2-3 feet or more. They seem to perform very well in this environment.

We added a 120 PA, which you can see here on the right end. Don’t worry - the tripod holding the Brunton is all aluminum. Still, this alignment methodology leaves some room for error . . .

We added a 120 PA, which you can see here on the right end. Don’t worry - the tripod holding the Brunton is all aluminum. Still, this alignment methodology leaves some room for error . . .

At Pole we had a Guralp Radian and Fortis, being logged by a Minimus. We removed these as their winter-over testing was complete. Note how the Radian is just installed straight into the snow, sort of like a big javelin. The Fortis (strong motion) is installed on a tile under the insulation. The bamboo poles were just to help support the plywood vault cover.

At Pole we had a Guralp Radian and Fortis, being logged by a Minimus. We removed these as their winter-over testing was complete. Note how the Radian is just installed straight into the snow, sort of like a big javelin. The Fortis (strong motion) is installed on a tile under the insulation. The bamboo poles were just to help support the plywood vault cover.

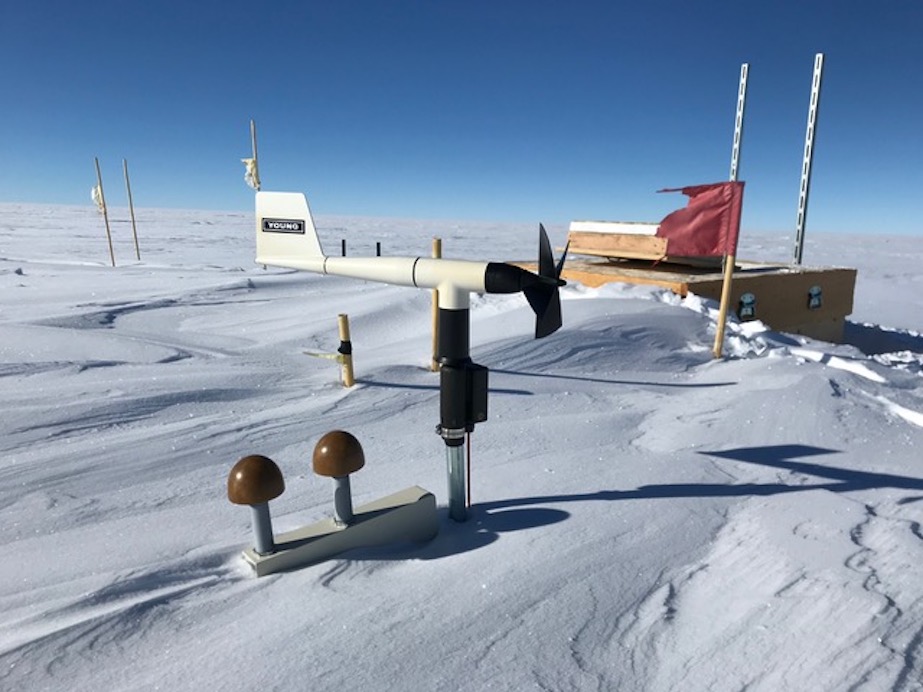

At the SPRESSO site at Pole we found the SPRESSO GPS antennas and anemometer nearly buried due to snow accumulation. We have been e-mailing with the USGS field engineers who will be here in a few weeks - they will extend the masts for these units so they are back up at a reasonable height (e.g., about 2 meters above the snow). The open hatch in the background provides access to a 25 foot ladder down to the SPRESSO recording room.

At the SPRESSO site at Pole we found the SPRESSO GPS antennas and anemometer nearly buried due to snow accumulation. We have been e-mailing with the USGS field engineers who will be here in a few weeks - they will extend the masts for these units so they are back up at a reasonable height (e.g., about 2 meters above the snow). The open hatch in the background provides access to a 25 foot ladder down to the SPRESSO recording room.

We installed a Kinemetrics MBB-2 seismometer directly into the snow in this mini-vault. We put a 2’ x 2’ piece of plywood over the top so the hole does not fill in (the plywood will rest right on the conduit). We have been putting all cabling in lightweight aluminum conduit to make it easier to dig things out of the snow without worrying about damaging the sensor cable.

We installed a Kinemetrics MBB-2 seismometer directly into the snow in this mini-vault. We put a 2’ x 2’ piece of plywood over the top so the hole does not fill in (the plywood will rest right on the conduit). We have been putting all cabling in lightweight aluminum conduit to make it easier to dig things out of the snow without worrying about damaging the sensor cable.

Finally, back here at MCM we have installed a 16 node charging / harvesting rack. We had 80 nodes shipped down for an experiment. We had a bit of a scare when the charging rack got a little wonky about how it determined the state of charge of the node batteries. The team in Socorro is investigating this not-seen-before issue. In the meantime, we re-charged every node before shipping them to the deep field, just to be safe.

Finally, back here at MCM we have installed a 16 node charging / harvesting rack. We had 80 nodes shipped down for an experiment. We had a bit of a scare when the charging rack got a little wonky about how it determined the state of charge of the node batteries. The team in Socorro is investigating this not-seen-before issue. In the meantime, we re-charged every node before shipping them to the deep field, just to be safe.

We even have the new single node charger and we pressed that into service as well.

We even have the new single node charger and we pressed that into service as well.

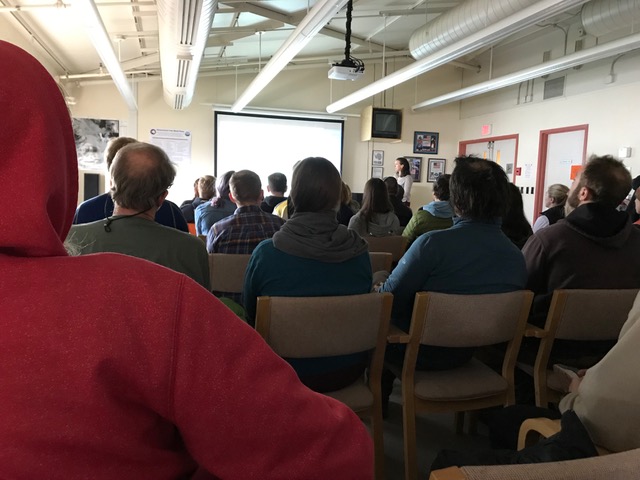

After charging the nodes, it was time to get all the gear packed for the UT El Paso team. They are heading out to an area on the West Antarctic Ice Sheet where they will be doing a relatively modest pilot experiment this year to test seismic wave propagation as a tool to probe the ice sheet, using small explosive charges as the seismic sources. Next year they will use what they have learned to design and execute an experiment on the Thwaites Glacier (a very remote location) to directly image the internal workings of the “shear zone” that is the boundary between very fast moving ice and ice that is hardly moving at all. Even their pilot experiment is going to be plenty hard work, with some very long days in the field. Over the next several years Thwaites will be the site of multiple experiments as part of a major US-British collaboration. There will be an extraordinary range of science being done. Wednesday evening I went to a lecture to learn about the whole set of experiments that are planned.

After charging the nodes, it was time to get all the gear packed for the UT El Paso team. They are heading out to an area on the West Antarctic Ice Sheet where they will be doing a relatively modest pilot experiment this year to test seismic wave propagation as a tool to probe the ice sheet, using small explosive charges as the seismic sources. Next year they will use what they have learned to design and execute an experiment on the Thwaites Glacier (a very remote location) to directly image the internal workings of the “shear zone” that is the boundary between very fast moving ice and ice that is hardly moving at all. Even their pilot experiment is going to be plenty hard work, with some very long days in the field. Over the next several years Thwaites will be the site of multiple experiments as part of a major US-British collaboration. There will be an extraordinary range of science being done. Wednesday evening I went to a lecture to learn about the whole set of experiments that are planned.

Back to the field prep. We palletize everything we can, so that things can be flown in an LC-130 Hercules out to the deep field camp. This camp, called WAIS Divide, is served by LC-130s, whereas many of the smaller camps are only reached by much smaller planes such as Twin Otters and Baslers. Here we are putting a cargo strap around the ubiquitous “tri-wall” cardboard box - this cardboard is thicker and stronger than any I have ever seen.

Back to the field prep. We palletize everything we can, so that things can be flown in an LC-130 Hercules out to the deep field camp. This camp, called WAIS Divide, is served by LC-130s, whereas many of the smaller camps are only reached by much smaller planes such as Twin Otters and Baslers. Here we are putting a cargo strap around the ubiquitous “tri-wall” cardboard box - this cardboard is thicker and stronger than any I have ever seen.

To get cargo out to the deep field we typically carry it out of the lab and pile it into a pickup truck.

To get cargo out to the deep field we typically carry it out of the lab and pile it into a pickup truck.

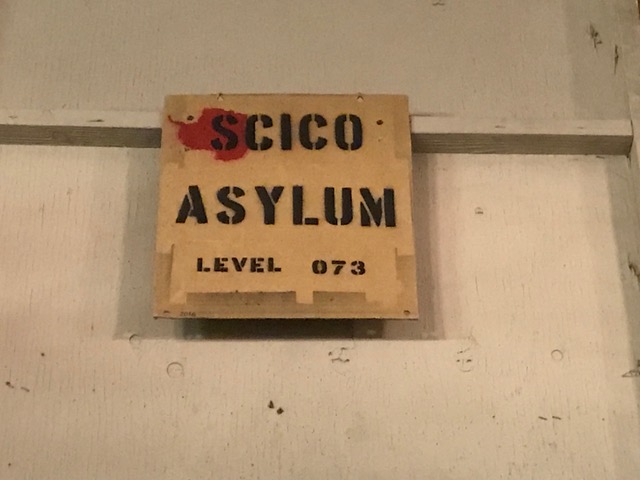

Then we drive it up the hill to “Science Cargo” (or SciCo, pronounced “psycho”) with a truck or a “pickle” forklift (for things that have been palletized).

Then we drive it up the hill to “Science Cargo” (or SciCo, pronounced “psycho”) with a truck or a “pickle” forklift (for things that have been palletized).

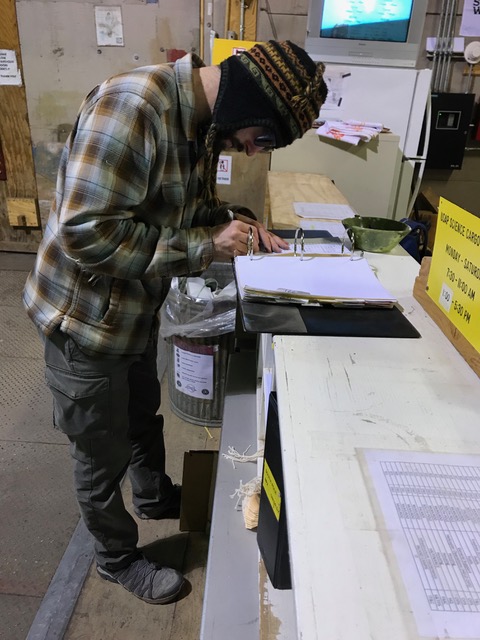

No cargo shipment is complete until the paperwork is done. You must specify the who, what, when, where, etc. if you want your cargo to get to the right place . . .

No cargo shipment is complete until the paperwork is done. You must specify the who, what, when, where, etc. if you want your cargo to get to the right place . . .

Well, that is about it. Lots of equipment check out, pack, and ship. In the meantime we are trying to get an infrasound sensor up and running to get it started on an over-winter test, using a new Campbell Scientific CR1,000X data logger. Makes me nervous running a new data logger, but the meteorology researchers down here all use this model and swear by it. They say this logger is rock solid for this purpose - relatively low dynamic range - but the infrasound sensor we are using it with is a sort of “strong motion” unit for use up-close to volcanoes. So the sensor and logger should be well matched.

Well, that is about it. Lots of equipment check out, pack, and ship. In the meantime we are trying to get an infrasound sensor up and running to get it started on an over-winter test, using a new Campbell Scientific CR1,000X data logger. Makes me nervous running a new data logger, but the meteorology researchers down here all use this model and swear by it. They say this logger is rock solid for this purpose - relatively low dynamic range - but the infrasound sensor we are using it with is a sort of “strong motion” unit for use up-close to volcanoes. So the sensor and logger should be well matched.

We ended today with my two teammates helicoptering up to Mt Erebus to work on a station. Departure time: 8:00 PM. Several more flights will be required, so we will all take turns, two at a time. The helicopters are landing at about 11,000 feet elevation, so we can’t send more than two people per trip. An A-Star for the people, a Bell 212 for the cargo. We are replacing all the batteries at each of four sites. We loaded the “General Lee” as a prelude to loading the helicopter, but we had to jettison about 140 lbs.

Hope my teammates don’t need the tools we had to leave behind. While they are working I went to the galley to get some Tikka Masala and Frosty Boy. But I’ll leave all these details for another post.

Hope my teammates don’t need the tools we had to leave behind. While they are working I went to the galley to get some Tikka Masala and Frosty Boy. But I’ll leave all these details for another post.